Sustainability

We pave the way for sustainability-driven innovation with our tire technology designed to define the future of our planet.

E.Circle Process

We remain committed to a sustainable environment from the initial process of designing tires to identifying the hazards of chemical substances used for our products throughout the planning, manufacturing,

and disposal processes.

Four approaches of E.Circle

As the global economy continues to grow, demand for goods is also increasing gradually. However, we must prevent resource exhaustion through efficient use as the resources given are not infinite.

Sustainable Resources and Materials Strategy and Goal

Our constant research spans the following four principles: recycling, renewable, reusable, reducing.

-

Recycle

Recycle

We reprocess waste tires to obtain the recycled rubber or the reinforcing filler, and use resources efficiently by replacing the petroleum-based raw materials with the recycled ones.

-

Renewable

Renewable

To contribute to resource conservation, we are actively discovering renewable raw materials and continuously developing technologies that apply them to our production.

-

Reuse

Reuse

Retreading tire technology, which converts the old tires in a good structural condition into new ones by covering them with rubber, we contribute to the environmental preservation by significantly reducing the amount of raw materials used.

-

Reduce

Reduce

We reduce the CO2 emissions with use of renewable energy and saving resources as well as the resource consumption by prolonging the use period while extending the lifespan of products.

Developing Sustainable Materials

Hankook Tire & Technology strives to reduce environmental impact from the tire design and raw material acquisition stages. By developing renewable and recycled raw materials and applying them to tires, the company is preventing depletion of natural resources and reducing carbon emissions.

Hankook Tire & Technology is contributing to reducing carbon dioxide emissions and preventing the depletion of natural resources by developing various sustainable raw materials and applying them to tires as shown below.

Use of Sustainable Materials

Hankook Tire realizes the eco-design that reduces negative impact on the environment by discovering and applying the eco-friendly materials to reduce the environmental impact of tire use and raw material acquisition. With active use of sustainable materials, we are achieving our result in preventing any depletion of natural resources and reducing CO2 emissions.

Developing Sustainable Tires

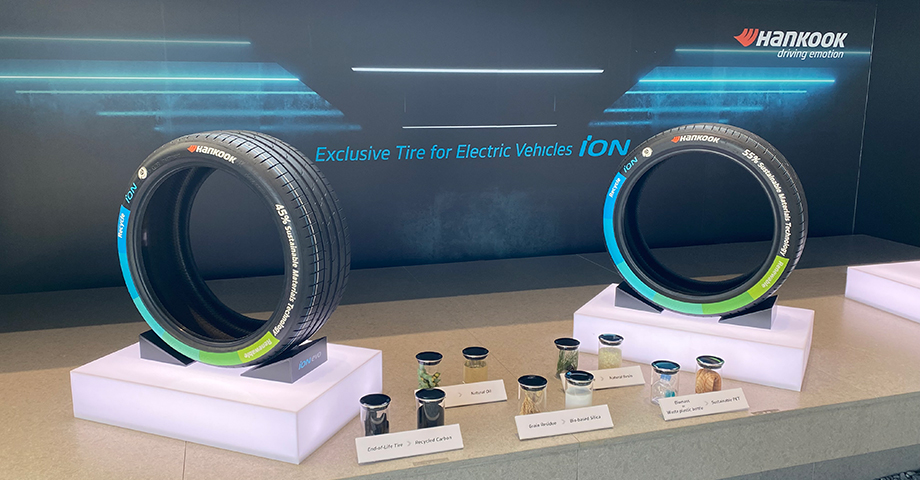

Hankook Tire is conducting various R&D activities to prevent resource depletion and reduce carbon emissions from the product development stage, where the environmental impact of tires is determined the most. In 2022, we succeeded in developing tires containing 45% of sustainable materials, satisfying both the legal requirements for passenger car tires and the requirements of demanding automakers. In addition, tires containing 55% of sustainable materials are developed successfully, and their durability is being evaluated in harsh conditions. Both tires contain sustainable raw materials such as ISCC PLUS certified synthetic rubber, recycled PET cord, recycled carbon black, bio-based silica, oil and resin. We will continue to conduct our research and development to use 100% sustainable materials for all tires by 2050.

Technology Collaboration of Eco-friendly Tire

Hankook Tire & Technology has focused on developing tires with excellent performance while using sustainable raw materials. A representative outcome of these efforts is the start of mass production of tires using 45% sustainable raw materials at the Hungary plant. With the use of sustainable materials, the company has developed its tires that maintain excellent tire performance and durability while contributing to reducing carbon dioxide emissions generated during the raw material acquisition stage. In this tire, sustainable raw materials certified by *ISCC PLUS such as bio-based silica, recycled PET cord, and bio-circular synthetic rubber were used in the mass balance method, and the industry's first ISCC PLUS certification logo was imprinted on the sidewall. In addition, the tires are being supplied to the high-performance electric sports car ‘Taycan facelift’ of supercar brand, Porsche.

* ISCC : International Sustainability and Carbon Certification

Developing sustainable raw materials with open innovation

Hankook Tire & Technology is actively collaborating with global raw material companies and contributing to the spread of circular economy businesses using waste.

-

Signed a business agreement (MOU) for development and business cooperation of eco-friendly tires using ‘Eco-SSBR’

Learn More -

Developing and commercializing ‘iON’, a tire exclusively for electric vehicles using Korea’s first chemically recycled PET fiber cord

Learn More -

Forming a network with domestic companies to establish a waste tire recycle system

Learn More